BASF ITALIA, PONTECCHIO MARCONI (BO)

BIERRE AUTOMAZIONI PROVIDES A “REINFORCED CLAMP FRAME”

The Client

With a turnover of around 74 billion Euro and a staff of more than 112,000 employees worldwide, BASF is the leading chemical company in the world. Its wide offer includes chemicals, plastics, performance products, agricultural chemicals, oil and gas.

In the plant in Pontecchio Marconi (Bologna), BASF Italia manufactures additives for plastics, in particular light stabilizers and antioxidants. And it does it devoting maximum attention to the effectiveness of quality systems, environmental protection and safety.

Its main customers are the plastic, automotive, packaging and agriculture industries.

The need

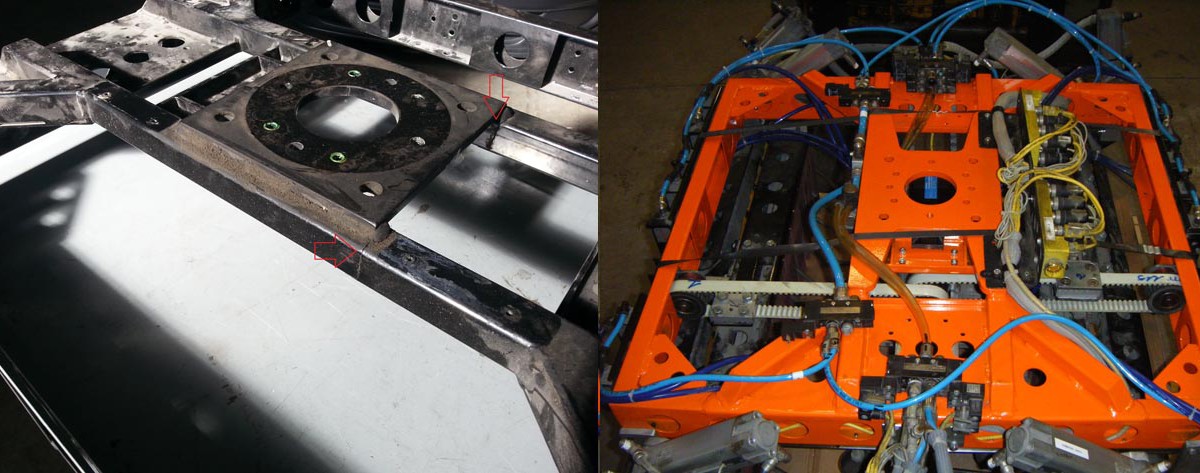

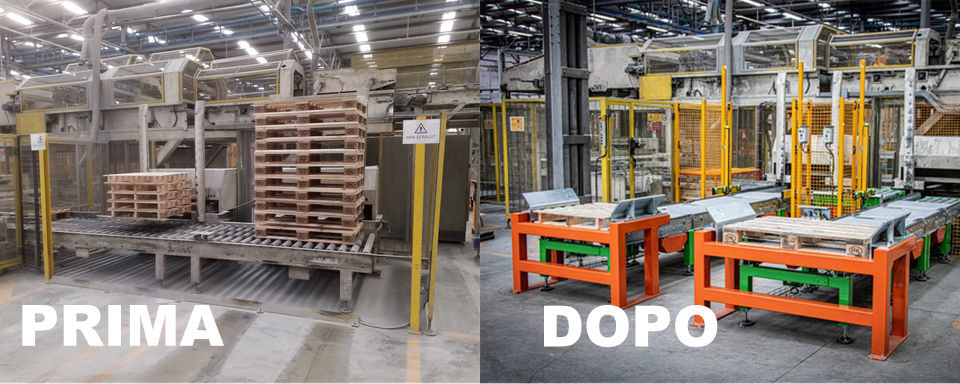

On the packaging line is a Robotic system having as picking accessory a movable gripper mounted on a specific frame. Due to use and vibrations the frame could run into breakages in the welding areas or in adjacent areas. Through an annual preventive maintenance contract, the line is subject to checks by the specialized technicians of Bierre Automazioni. It was during one of these scheduled visits that the subsidences were detected on the supporting structure of the mobile device.

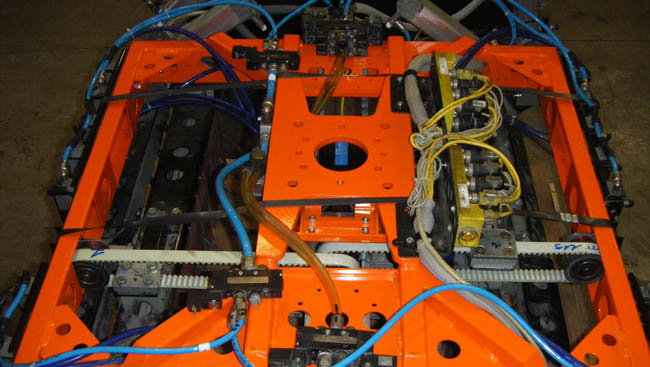

Following the warning, in order to avoid subsequent sudden and unplanned downtime periods, Basf Italia asked Bierre Automazioni to perform technical analysis that would allow to replace the gripper, through the provision of a new reinforced frame and the recovery of mechanical and electrical parts installed and not damaged.

Furthermore, the solution had to provide a reduced plant downtime period, in order not to burden the production times of the line itself.

The solution adopted

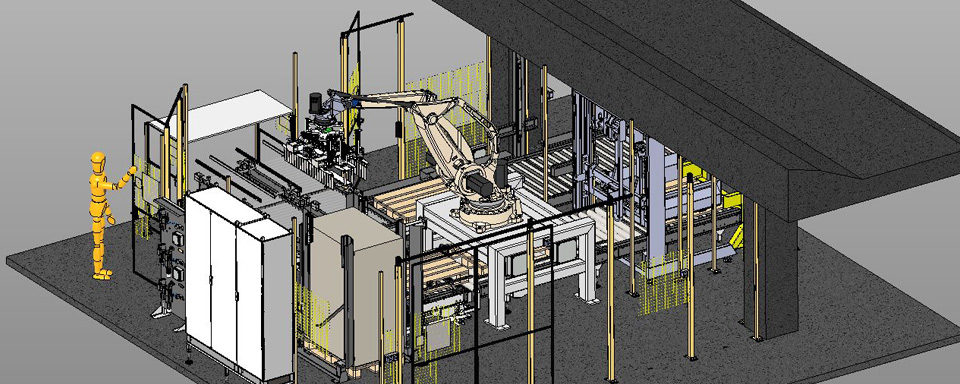

Bierre Automazioni proposed Basf Italia the construction of a new reinforced frame with special welding specifications made by its engineers. The technicians would then seek the recovery of the old gripper, preparing to mount the new frame at their workshop, that is directly at Bierre.

The undamaged recoverable material would be reassembled on the new structure and repositioned on the line so as to ensure the minimum downtime period of the system.

I RISULTATI RAGGIUNTI

“After an intervention concluded in short time, the new frame proved to fit the technical specification required and the production was able to restarted in safety way.”

Contatti: Fabrizio Maestri (f.maestri@bierreautomazioni.com)