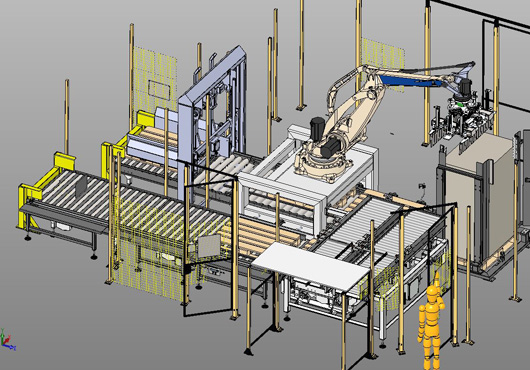

BIERRE AUTOMAZIONI CARRIES OUT THE DESIGN/CONSTRUCTION/COMMISSIONING OF A ROBOTIC WORKSTATION FOR BOXES.

The customer

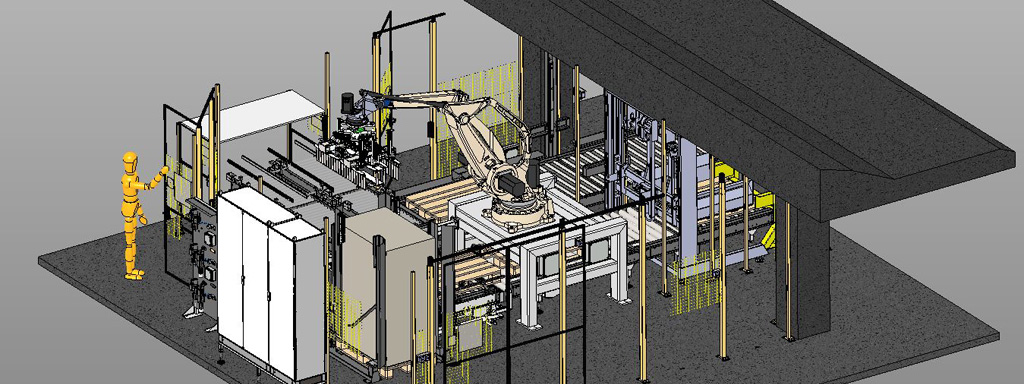

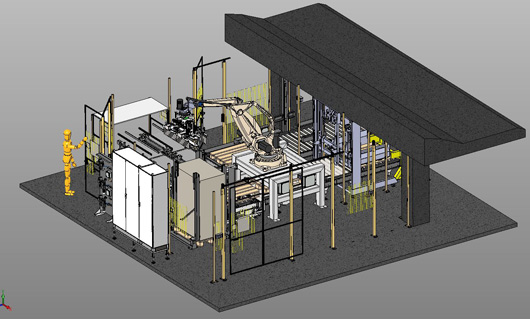

Following numerous requests for robotic workstations aside from those for bags, a well-known manufacturer of automatic systems entrusted Bierre Automazioni with the turnkey project of a Robotic Workstation for the management of cardboard boxes.

The need

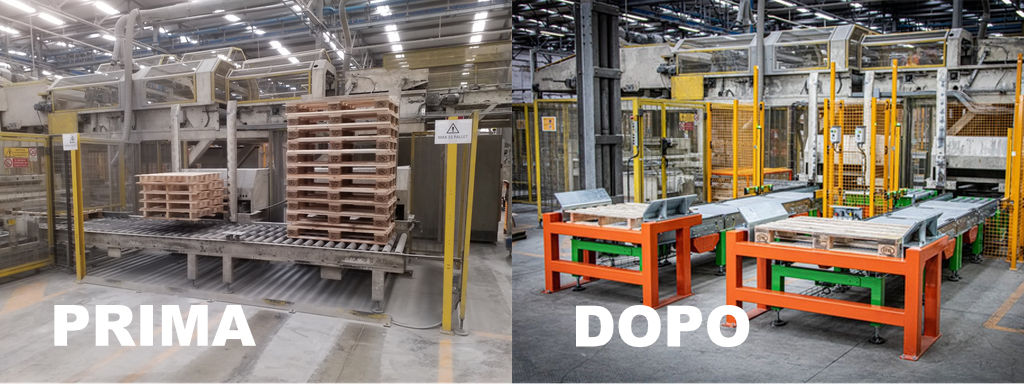

The purchaser, a leading chocolate producer with a factory in Switzerland, commissioned our Customer to build a new robotic workstation, replacing an old robotic palletiser already present in the plant.

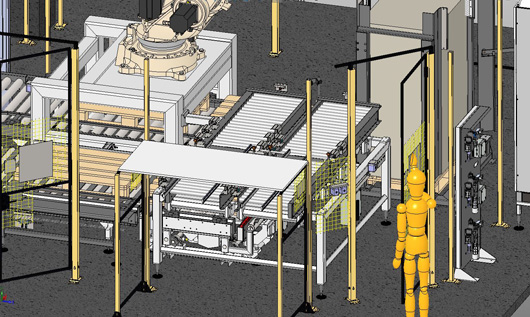

Bierre Automazioni had to guarantee the complete management of the project, in all its phases: A complete mechanical/HW/SW project according to the specifications and requirements of our Customer, pre-assembly at the workshop, pre-testing, installation and commissioning at the Purchaser’s factory.

The solution chosen

Bierre Automazioni committed to the project, adapting itself to the requirements of the specifications and the guidelines of our Customer. It built the entire workstation meeting tight deadlines with a “turnkey” solution, freeing the Customer from any technical/logistics management issues involved in the order.

Contacts:

Fabrizio Maestri

Sales Manager / Senior Engineer

(f.maestri@bierreautomazioni.com)