ALLNEX ITALIA SRL, ROMANO D’EZZELLINO (VI)

BIERRE AUTOMAZIONI PERFORMS THE PROVISION OF A FILLING LINE OF 200 KG DRUMS IN AREA CLASSIFIED AS ATEX 2-22

The customer

ALLNEX ITALY SRL. Allnex Italy, is a chemical company of Romano d’Ezzelino manufacturer of polymer materials for industry and more specifically of powdered resins.

In summary it produces and process polymers for the industry and for the protective applications and chemical products in general.

The need

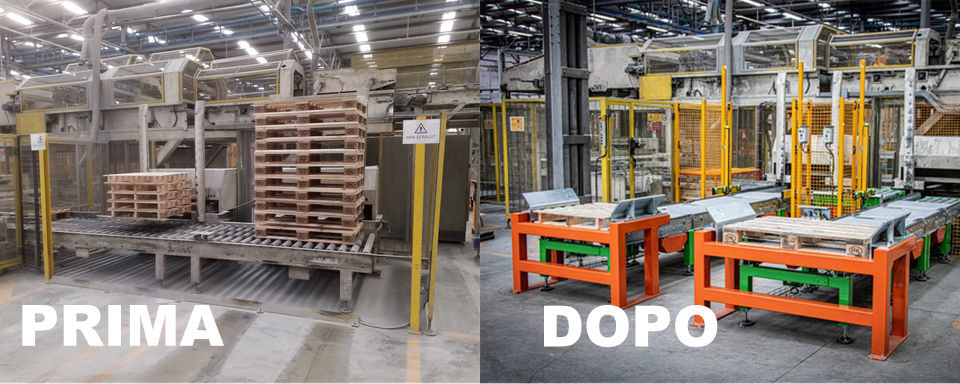

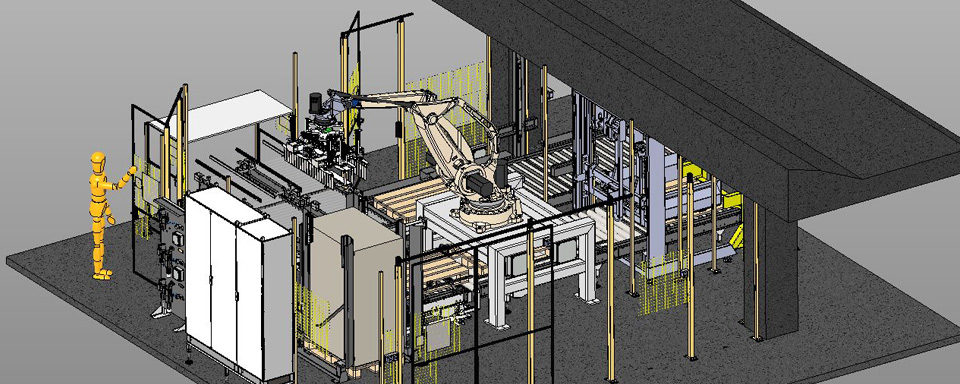

In one of the working lines within a 2G ATEX classified area, it was necessary the management of 1200 x 1200 mm pallets containing 4 drums each 200 kg, to be filled with liquid products in an automatic way, without the intervention of operators in the dosing area.

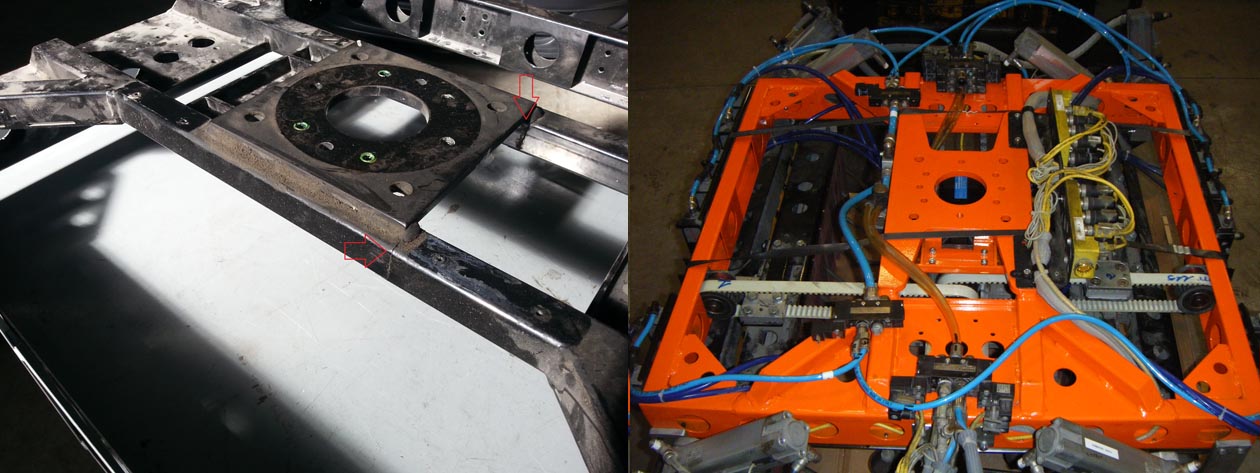

The filling was to be controlled by an ATEX load cells system arranged under the carriage roller.

The load of the empty pallets had to take place through the placement of pallets by operators using low Pallet trucks.

This requirement, as well as the need of performing the activities within an area classified ATEX 2G area, required the use of transport roller with non-standard heights, specifically designed. Because of the very small lower space, motion control of rollers should have occurred with laterally installed motors with respect to the transport.

The drums, once filled, would have had to move towards a full pallets unloading-collecting area.

The solution adopted

Bierre Automazioni has proposed and provided to Allnex Italy Srl. a series of transport with reduced height, without the use of the weighing roller retaining hole, having ATEX engines with side mounting and ATEX sensors for the control of the presence of the pallets laterally installed to transport sides themselves.

RESULTS ACHIEVED

“Thanks to the provision designed and built by Bierre Automazioni it has been possible to realize a filling line in ATEX classified area without resorting to excavation works, while ensuring the maintenance of off standard transport heights loadable through pallets handling system of the Transpallet type.”

Maintenance Department – ALLNEX ITALY SRL – plant in Romano D’Ezzellino (VI)

Contact: Fabrizio Maestri (f.maestri@bierreautomazioni.com)