SUPPORT

SUPPORT

Bierre Automazioni offers installation, start-up and commissioning services worldwide, supported by specialized technicians and tele-assistance availability. It guarantees a fast and competent after-sales support on mechanical, electrical, electronic and robotic installations. It provides scheduled and preventive maintenance, ensuring operational continuity and management of maintenance contracts. It is specialized in the revamping of machines and complex systems, to extend their life cycle according to current standards. The offer is completed by the spare parts service and the Bierre Academy program for the technical training of customers and operators.

SUPPORT

Installation

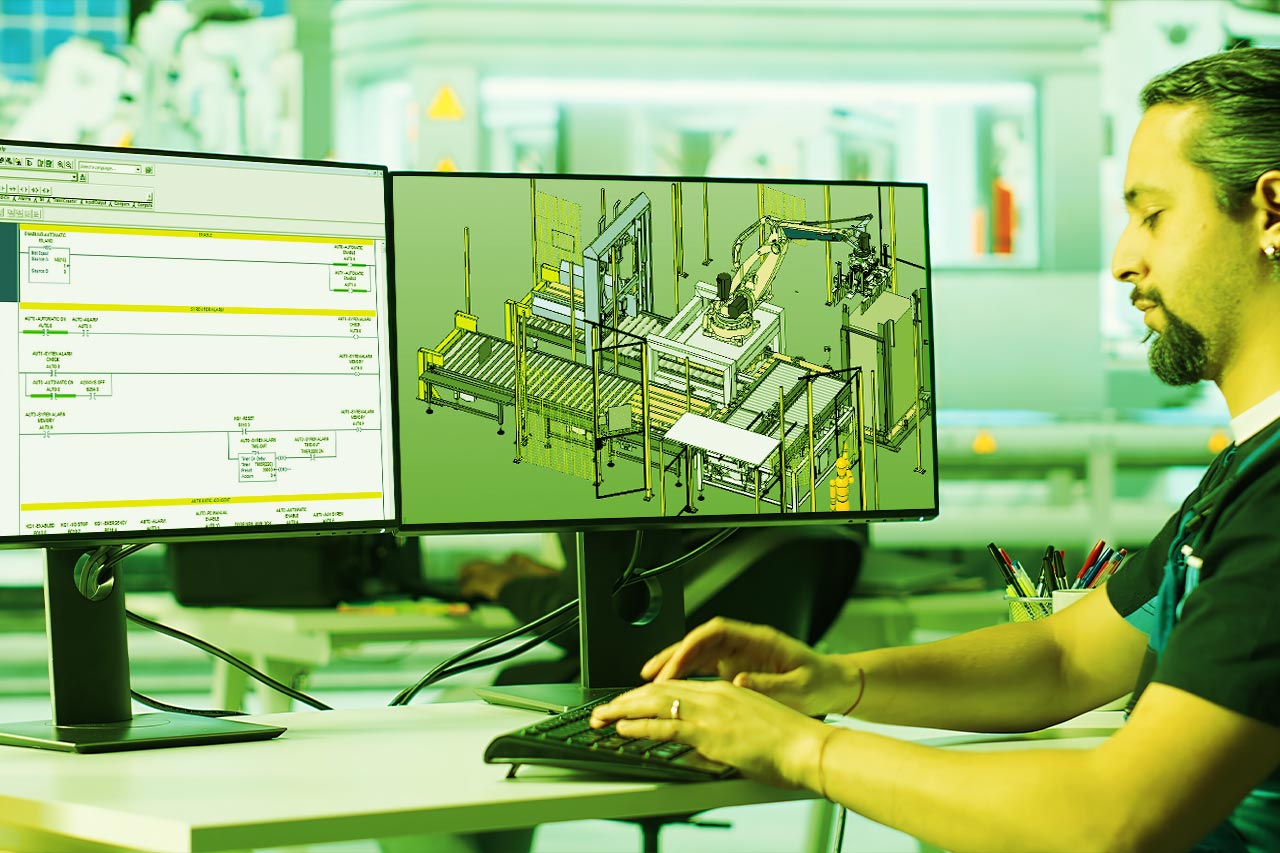

Bierre stands out for its ability to offer and carry out installation, start-up and commissioning interventions for systems both of its own production and of OEM manufacturers in every region of the world, ensuring a top-quality service and a global presence.

A team of highly qualified technicians, specialized in mechanical, electrical and software areas, works with dedication and expertise, so as that every project is completed on time and according to the best standards of quality, precision and safety.

The professionalism and experience of Bierre staff are the beating heart of the company’s mission, allowing us to positively face even the most complex site situations.

In addition, Bierre provides an effective tele-assistance service, which permits to remotely connect to machines, in real time, directly from the office, representing an additional level of support during on-site activities, granting to promptly intervene and optimize the time needed to resolve any issues.

SUPPORT

Assistance

Assistance is one of the pillars of Bierre’s mission, and it represents one of the main added values of the company’s daily business, with the stated aim of serving national and international clients, so to build strong and long-lasting relationships of trust.

The after-sales division is structured to maximize the operational continuity of customers’ production lines: a team of experienced and qualified technicians is available to quickly respond to various needs, optimizing the operations and minimizing the downtime in the event of a failure.

The preparation and professionalism of Bierre’s customer service members allow to intervene in a variety of emergency situations, mechanical, electrical and electronic, including the ability to work on programs running on old Siemens, Rockwell Automation, Telelecanique, Klockner-Moeller and GE PLCs, and on latest generation PLCs and PCs, as well as the expertise in the knowledge of the software of the robotic systems of the main families of anthropomorphic robots such as Fanuc, Kuka, Kawasaki, ABB, Comau, Yaskawa and Motoman.

The ability to connect via telea-ssistance allows to provide remote support to diagnose hardware and software issues and to intervene in real time.

In case of need, on-site technical interventions by Bierre professionals are then quickly organized, ensuring promptness, expertise and quality everywhere in the world.

SUPPORT

Maintenance

Bierre offers scheduled and preventive maintenance solutions, designed to ensure the highest level of reliability and performance of the systems.

These maintenance plans include periodic visits to check the status, so to promptly identify any critical issues and, in case, to arrange interventions.

The main goal is to prevent any stop of the line, reducing the risk of downtime and ensuring the continuity of production processes without interruption.

By virtue of the skills gained over time, Bierre is also able to assert itself as a reliable partner to manage the general maintenance of large industrial lines and entire plants, both with staff on site and with personnel from our headquarters depending on the size of the works and the specific needs.

Thanks to a proactive and customized approach, Bierre serves its customers to maintain the plants in the long term to assure the proper efficiency, performance and safety.

SUPPORT

Revamping

The thirty years of experience on field make Bierre a partner of absolute competence for the revamping service, including the activities and the interventions aimed to extend the life cycle of the existing machines and plants, and to restore their performance and capabilities, thanks to the study and the design of reliable and sustainable solutions for adapting systems to the state of the art of current manufacturing standards, and for updating safety devices to the current regulations.

Bierre team of specialists is able to ensure the complete refurbishing of existing machinery, improving its efficiency by replacing old and worn mechanical, electrical, and electronic parts with present modern technology components, thus restoring the performance of a machine that would otherwise have had to be replaced by a new one, resulting in lower investment costs and reduced execution times.

The expertise of Bierre staff allows to provide added value in every area of possible revamping of devices of various types and brands:

- mechanical overhauling, such as the renovation and remake of mechanical parts and components;

- electrical and electronic implementation, such as replacing obsolete PLCs;

- automation software updates and improvements.

In addition, each revamping project carried out by Bierre is completed with the new technical documentation of the machines, including the files of risk analysis and safety compliance.

The main advantages of a Bierre overhauling work include the increases of performance, usability, safety, and, more generally, the improvement of quality and sustainability of the entire production cycle, which benefits significantly from the modernization and efficiency achieved with this type of intervention.

Bierre is thus also synonymous with extending the service life of existing plants.

SUPPORT

Spare parts

A key element which distinguishes Bierre is the spare parts service, which ensures the availability of components and their timely delivery around the world. This is possible through a fast and efficient order process, which allows to customers receiving parts in the shortest time, ensuring reliability and business continuity.

In case of new installations, Bierre provides a detailed list of recommended spare parts at the machine delivery. This list includes both first aid parts, essential for line operation, and parts with long availability period, thus facilitating customers in evaluating and planning spare parts procurement, relying on a more effective management of the spares in the warehouse, and on the ability to promptly intervene in case of need.

Thanks to the experience and the expertise acquired over the years, Bierre also can manufacture spare parts by drawing, adapting them to the specific needs of the existing systems. This is realized through detailed site surveys carried out by Bierre experts, or through technical files provided directly by the client. When it’s possible, Bierre commits to manufacture updated versions of such components, with the aim of improving the life cycle and the overall performance of the equipment, thereby helping to optimize efficiency and duration.

SUPPORT

Training

Continuous training has always been one of Bierre’s cornerstone pillars, resulting in the constant updating of its specialists, who regularly participate in courses on the latest technologies and software releases in the market.

Over the years, Bierre has developed the vocation and willingness to proactively train the personnel of its clients, both OEM integrators and final end-users, confirming its dedication to assistance service and to total customer’s satisfaction, in the belief that trained operators make a fundamental contribution to improving efficiency, increasing performance, preventing downtime risks and preserving the safety and the life cycle of the installations.

Thus, BIERRE ACADEMY was born a few years ago, a structured training program, both in the classroom at our headquarters or at the client, and on the field, which is available to our clients’ technicians to learn the state of the art of the general and specific know-how of the automation for the packaging industry.

Bierre Academy course arrangements are tailored to suit the individual client’s needs, with maximum flexibility regarding the duration, including multi-year possibility, and the targets of the level of expertise to be achieved.

Thanks to the experience of Bierre professionals, at the end of the training period, the client’s technicians will be adequately prepared and trained by the theoretical and practical point of view with a high level of confidence and skill.