BIERRE AUTOMAZIONI OFFERS ITS KNOW-HOW BY PROVIDING SAFE AUTOMATED PORTALS, ORDERED BY A SPANISH CUSTOMER

Our needs

Our customer constantly aims at enhancing approaches in developing safer factories, to protect its employees.

For this reason, our customer’s HSE department has decided to review the establishment’s warehouse storage management system. As of today the palletization of bulk and packaged products is performed with bag palletisers on pallets, transferred to the lower deck through various automated lifting systems. These lifting systems are barrier-free on the pallet roller input side; therefore an unobservant operator could (walk on roller conveyors’ safety system) accidentally fall into the chamber in which the pallets are inserted ready to be transferred to the lower deck where they are stored.

This very dangerous situation is monitored impeccably, but it is widely known that the precautions taken in these cases are never enough and the Machinery Directive 2006/42/EC requires greater efforts which is why Bierre Automazioni is entrusted to design and construct a replicable portal on 4 “finished pallets” storage lines.

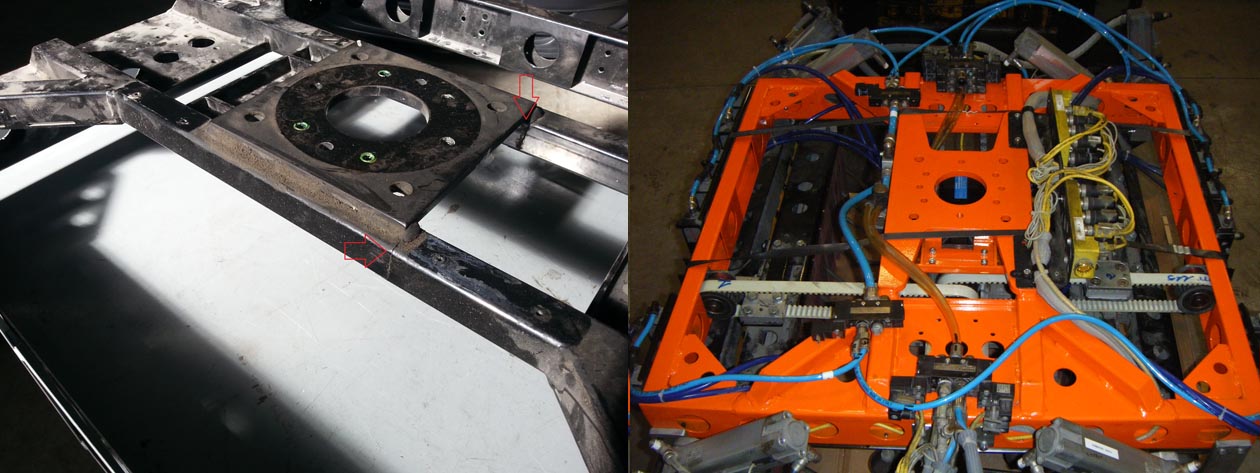

Furthermore the system cannot accommodate such a radical change to reposition sensors on transport systems while performing technical tests to avoid the removal of operating machinery and their demolition.

The solution

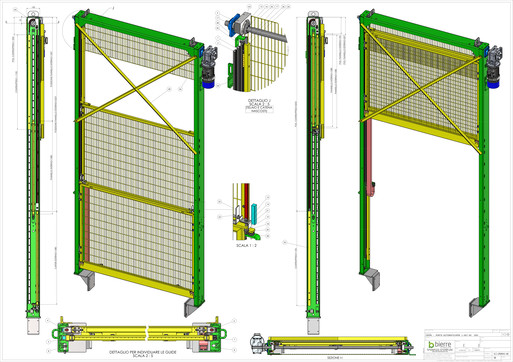

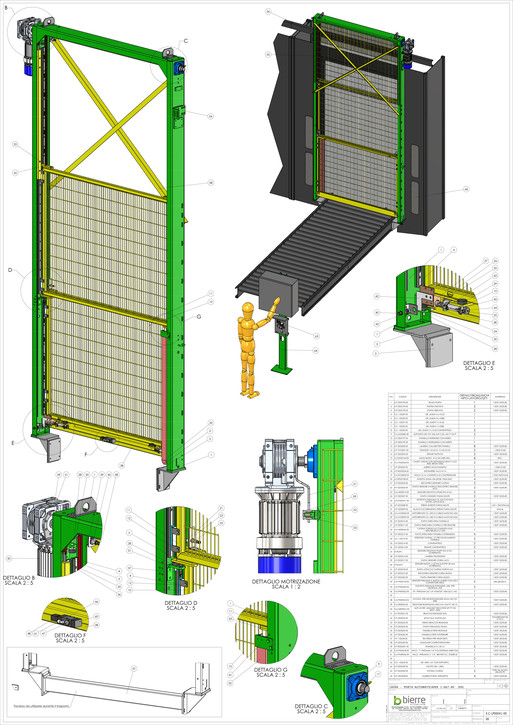

Bierre automazioni offers the production of anti-fall automated portals to its Spanish customer as recommended by UNI-EN 415-4 for all package pending load devices.

These shutters may apparently seem trivial, but are based on an accurate study by our technical office which has once more been able to obtain a slender product that can perfectly fit the machinery in the plant. The pictures illustrated show how adjustments not provided for during research were in any case irrelevant (because of plants’ poor maintenance when revamping) rather than excessive sensors across the line.

Each portal is equipped with:

- An electrical switchboard with a small incorporated PLC monitoring: movement, open commands, upstroke and downstroke movement, and a faulty portal which gets blocked;

- Safe pneumatic dump valve for the anti-fall locking device; this system guarantees getting rid of shearing hazards;

- Precision mechanics with counterweights, to minimize electric motor strain;

- Sensors to monitor the portal;

- Partly completed CE marked machinery;

- Requirement of UNI EN 415-4 and Machinery Directive 2006/42/EC design;

Bierre Automazioni shall install 4 portals in 6 business days to be tested on the seventh day. This effective and efficient system has been greatly appreciated by the customer.

Results

“Thanks to the new portals installed by Bierre Automazioni and revamped machinery, our customer has met the Machinery Directive’s requirements ensuring high safety standards which prevented the demolition of existing installations, by innovating them.

Bierre Automazioni provided machines, but also integrated various system parts thus avoiding unnecessary waste and ensuring excellent financial savings. ”

Contact:

Maicol Garavaldi

Proposal Engineer

(m.garavaldi@bierreautomazioni.com)

Contact:

Fabrizio Maestri

Sales Manager / Senior Engineer

(f.maestri@bierreautomazioni.com)