BASF ITALIA, PONTECCHIO MARCONI (BO)

BIERRE AUTOMAZIONI FORNISCE UNA “MACCHINA VIRTUALE” PER LA SUPERVISIONE IMPIANTO

The Client

With a turnover of around 74 billion Euro and a staff of more than 112,000 employees worldwide, BASF is the leading chemical company in the world. Its wide offer includes chemicals, plastics, performance products, agricultural chemicals, oil and gas.

In the plant in Pontecchio Marconi (Bologna), BASF Italia manufactures additives for plastics, in particular light stabilizers and antioxidants. And it does it devoting maximum attention to the effectiveness of quality systems, environmental protection and safety.

Its main customers are the plastic, automotive, packaging and agriculture industries.

The need

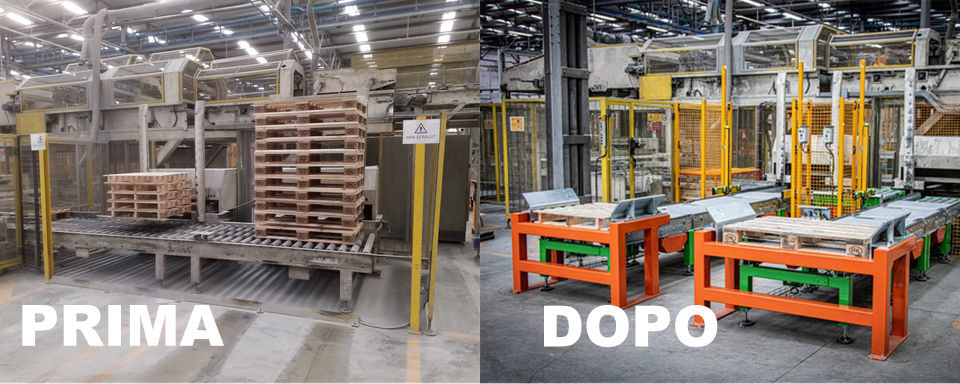

Basf Italia contacted Bierre Automazioni to perform work on the centralised control system of the packaging line present in the plant. The system is made up of several machines that operate up to the delivery of the pallets to the logistics department.

The centralised control system of the plant did not have a complete Back-up for the supervisory PC. In the event of a PC Fault, system management may be interrupted with resulting extended downtime of the line.

The solution chosen

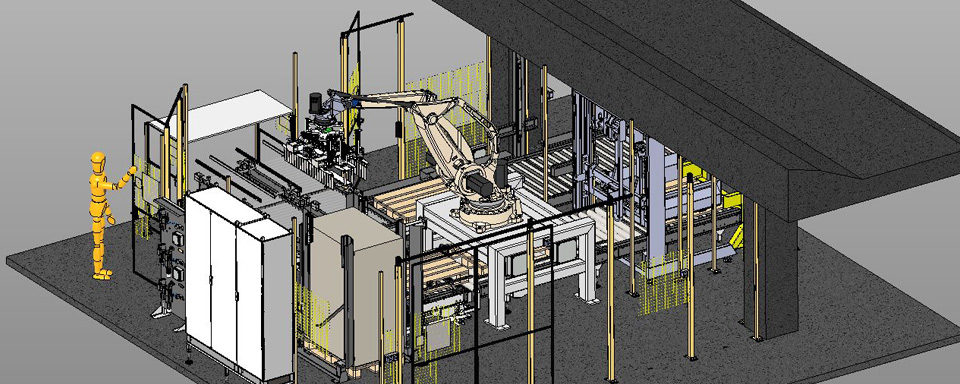

Bierre Automazioni proposed Basf Italia the creation of a physical image of the supervisory PC, complete with all management programs and software for the line.

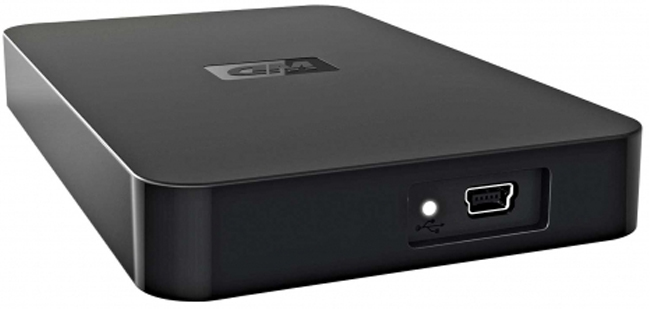

Rapid replacement of the faulty PC with a new PC is achieved through a virtual machine containing the original configurations (PC Ghost). Thanks to the work by Bierre Automazioni, it has become possible to monitor continuity, even in the event of a FAULT with the supervisory PC.

RESULTS ACHIEVED

“Following the work, in the event of a fault, internal staff will now be able to activate supervisory mode in an emergency – and in less than 15 minutes – from any PC linked to the system.

By performing a supervisory PC FAULT simulation, it is possible to restart the control of the entire line in the required times by using any PC activated using the virtual machine’s hard disk connection. “

Contacts: Fabrizio Maestri (f.maestri@bierreautomazioni.com)